Exploring Convergence of Snake Skin-Inspired Texture Designs and Additive Manufacturing for Mechanical Traction

Student: Catherine Tiner

Degree: M.S., December 2019

Major Professor: Dr. Ajay Malshe

Research Area(s):

Nanoscience & Engineering

Photonics

Background/Relevance

- Textures in nature can be exploited to benefit industrial applications.

- Surfaces interact with aggressive environmental factors.

- Snake scales are composed of micro-denticulations and rough edges which allow the snake to grip the ground.

Innovation

- To take examples of the textures found on snake skin and write similar textures derived from that architecture. Analyze laser processed surfaces for microstructural and chemical modifications.

Approach

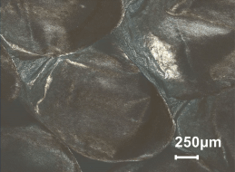

- Use of a laser-powder bed fusion process to write architecture of the scales that form snake skin.

- Laser microfabrication allows for complex patterns to be written.

- 3D written microstructures are chemically and physically analyzed.

- Will implement patterns onto metals to test their frictional parameters.

Key Results

- Studied snakes skin using profilometer and identified the major advantages to the structure.

- Designed and 3D printed our own “skin”.

- Tested the anisotropic frictional properties due to the laser patterning and compared to real snake skin.

Conclusions

- Observed a periodic increase and decrease following micropattern’s periodicity.

- This demonstrates that snake-skin micro texture could control traction at microscale by periodic modulation of micro frictional properties of 3D printed material.

- Larger scales and smaller scales were tested to prove that the anisotropy is present due to the micro patterning and not the size of the overall scale.

- Overall, a snake skin-insprired 3D texture was successfully manufactured and showed clear anisotropic frictional properties.