Localized Electrodeposition of Gold Using Photodoped Cuprous Oxide

Student: Elizabeth Johnson

Major Professor: Dr. Robert Coridan

Research Area(s):

Energy Materials & Devices

Background/Relevance

- Traditional lithography of gold is extremely expensive and requires the use of a clean room

- Cuprous oxide is earth abundant and efficient at performing galvanic replacement reactions

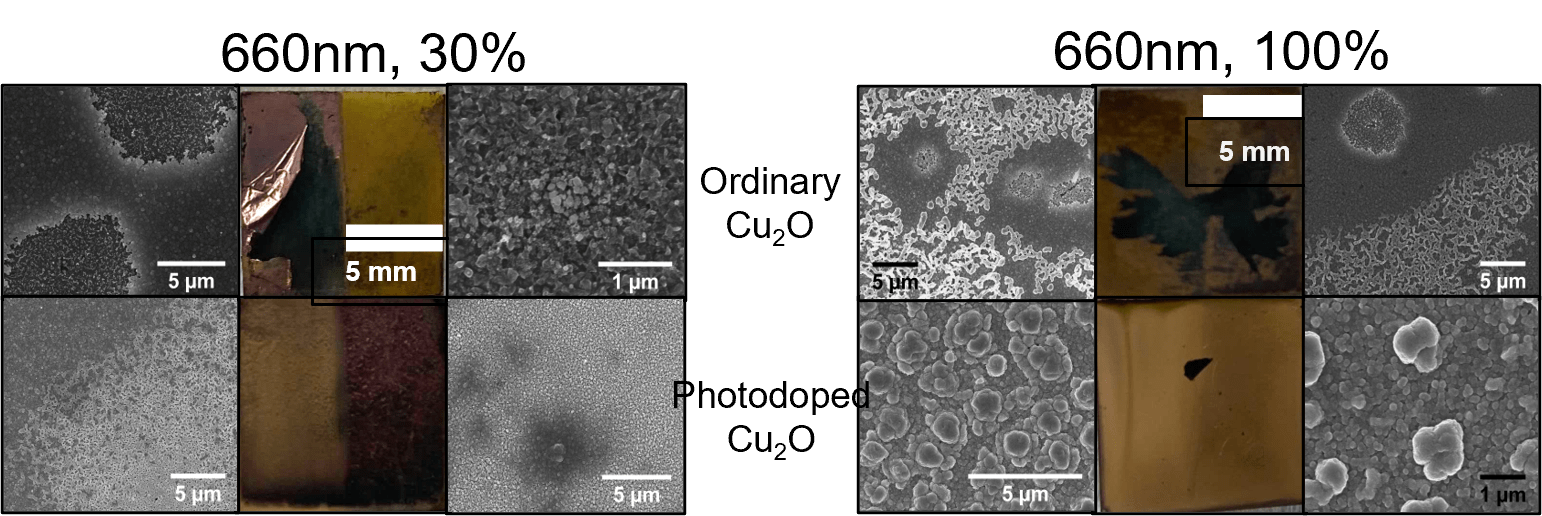

- Can locally photoelectrodeposit cuprous oxide using LED light with a photomask, producing photodoped cuprous oxide containing cuprous oxide and copper metal nanocrystals

Innovation

- Can electrodeposit gold onto localized photodoped cuprous oxide, providing a way to produce microprocessors on the bench without the use of a clean room

Approach

- Synthesize gold metal solution

- Using a potentiostat, deposit layer of gold onto FTO, cuprous oxide, and photodoped cuprous oxide to test abilities of gold solution

- Test similar conditions with external illumination (660 nm red LED light)

- Pattern the electrodeposition of gold using a photomask

Key Results

- Before gold starts electroplating onto the substrate, the cuprous oxide first reduces to copper

- The gold layer adheres better to the photodoped cuprous oxide than ordinary cuprous oxide

Conclusions

- Adding light to electrodeposition increase the rate of gold electroplating

- There is some heat transfer that occurs between light and dark sides, causing similar electrodeposition rates between lit and non-lit sides of the substrate

- Electrodepositing gold onto localized photodoped cuprous oxide will provide a way to produce inexpensive, noble-metal electrodes for micron-scale processes on the bench without the use of a clean room