Studying Thermal Roughness in Induction Heated Iron Nanoparticle Laced Sorbitol Films

Student: Jon Matutes

Major Professor: Dr. David Huitink

Research Area(s):

Nanoscale Materials & Devices

Background/Relevance

- Induction heating of nanoparticles has a wide variety of applications, from potential cancer treatment to improved efficiency of chemical reactions.

- Induction heating of nanoparticles can provide more precise control over the heating of a substance, as well as quicker heating.

Innovation

- The thermal roughness of induction heated nanoparticles has received little study.

- Understanding the relationship between nanoparticle distribution would further other developments in the field.

Approach

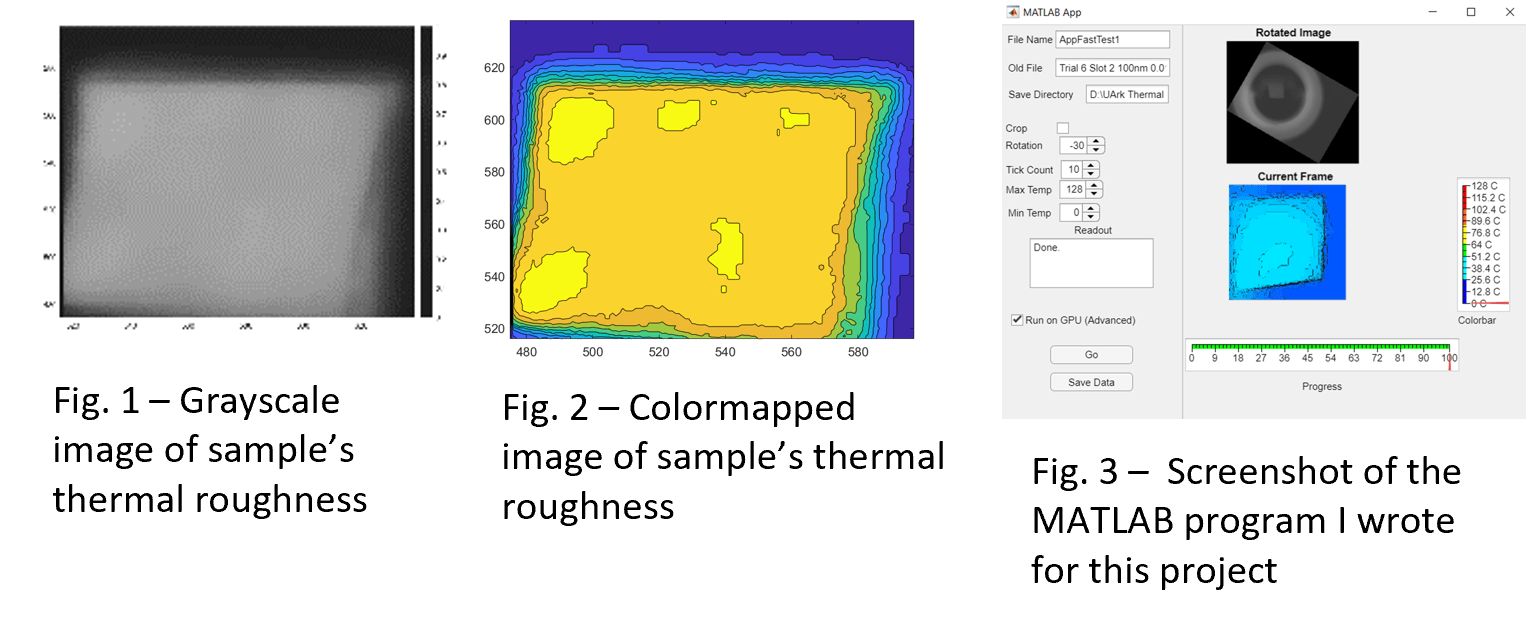

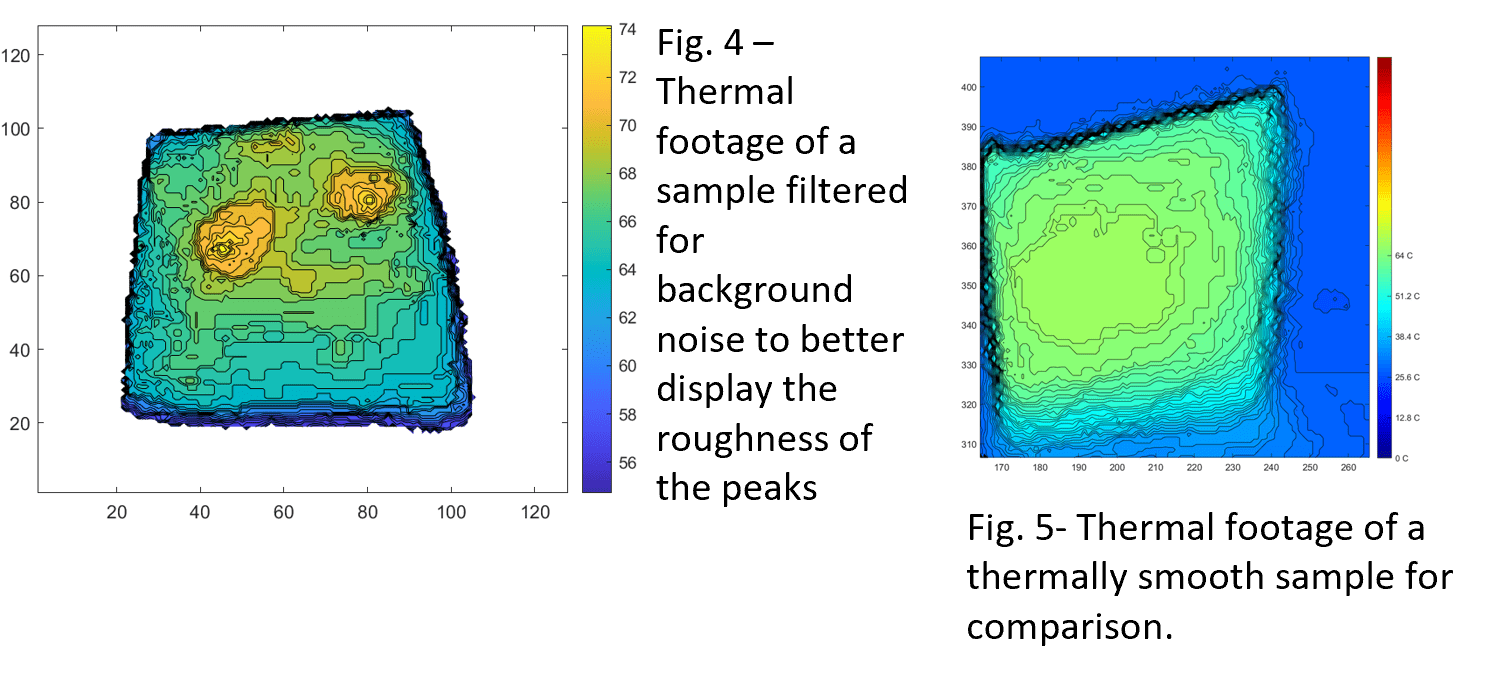

- Using MATLAB, colormaps can be created of thermal roughness from IR footage.

Key Results

- Some samples showed unexpected thermal roughness

- These samples possessed at least one ‘peak’ where the temperature was at least 10 C above the mean of the sample

- These peaks were only present during the heating process.

Conclusions

- Since the peaks were only present during heating, it was concluded that they are due to nanoparticle distribution

- Spin casting processes are likely to produce better thin films for study than drop casting, but our procedures need work

- Future work is likely to involve determining causes for this thermal roughness and developing better methods of creating thin films via spin cast.