Controlling the Coating Thickness of Polydopamine on Nanoparticle Surface

Student: Nazar Orishchin

Major Professor: Dr. Jingyi Chen

Research Area(s):

Nanoscience and Engineering

Background/Relevance

- Polydopamine (PDA) is an effective adhesive that can be used on inorganic and organic materials.

- PDA is biocompatible and can be used for drug delivery and membrane separation applications.

- PDA coated nanoparticles (NPs) have been used as fillers to increase wear resistance of thin film coating such as polytetrafluoroethylene (PTFE) commonly known as Teflon.

Innovation

- Controllable PDA coating thickness on NPs can improve tribological properties of these fillers in surface coatings, as well as optimize the loading capacity of drug molecules in these NPs for controlled release.

Approach

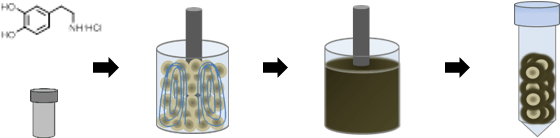

- Identify methods of uniform PDA coating process.

- Examine effects of dopamine (DA) and NP concentration on PDA coating formation for the same batch of NPs.

- Study effects of different batches of NPs on PDA coating formation to establish a versatile method.

Key Results

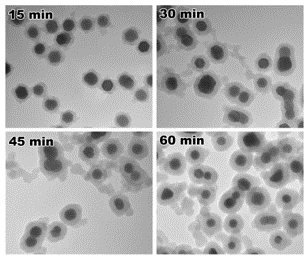

- Uniform PDA coating with minimal free PDA on NP surface was achieved at the reaction condition of 1.70×104 molecules/nm2.

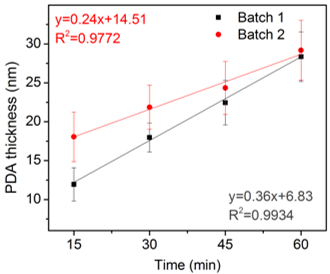

- PDA coating thickness linearly increases with reaction time.

Conclusions

- Dispersion method was chosen over sonication because of coating uniformity result and shorter synthesis time.

- Higher DA concentration results in thicker PDA coating while larger amount of particles results in less free PDA particles.

- PDA thickness is reaction time dependent.

- DA concentration to surface area determines heterogeneous nucleation over self-nucleation of PDA formation.

- PDA on NP surface is more stable than that of free PDA.