Development of Bases and Floor Connection for Swarm 3D Printers

Student: Samuel N. Gunter

Major Professor: Dr. Wenchao Zhou

Research Area(s):

Mechanical & Structural Materials

Background/Relevance

- Modern production lines often require specialized equipment and procedures, limiting adaptability and long-term autonomy.

- Swarm manufacturing can achieve long-term autonomy via the cooperation of many autonomous manufacturing robots.

- Base of the current design of the autonomous manufacturing robots needs to be improved.

Innovation

- Design of autonomous manufacturing robots to enable swarm manufacturing..

- Improve the base design and reliability of the activation mechanism with mechanical activation.

Approach

- Printers are designed to have one support, or one point of contact with the floor, so that they can be as compact as possible.

- The base must be sturdy and reliable, since there is no other floor connection.

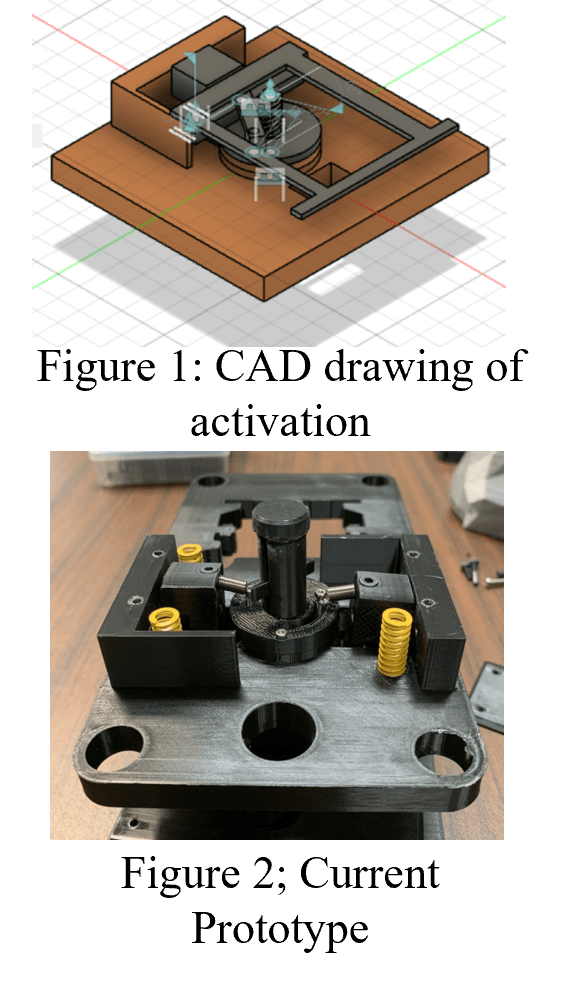

- The current base for the printer is 3D printed and shall be redesigned with metal replacement of housings and joints of the printer.

- The new base should attach to the floor tiles in a completely mechanical fashion, to eliminate power usage from the current base which uses an electric motor to grip the floor tiles.

Key Results

-

A successful prototype base was produced that provides sufficient force to hold a printer unit in place under expected conditions.

-

The new base operates by supplying tension to two latches that grip the floor tile. The latch is activated on setting down the printer, which engages the latches and turns a screw that applies tension to the latches.

-

The release is activated by the motion of the mobile platform.

Conclusions

-

The new base mechanism was designed to fit within the space of the new printer design and accomplishes this by restricting its size to a 94mm x 54mm x 18mm volume.

-

The design does not require any type of motor to activate the latches, it is wholly reliant on the movement of the printer and mobile platform, and thus satisfies the requirement to be fully mechanical.

-

With the added weight expected from the redesigned printer unit, and sufficiently strong tension springs, the mechanism should provide sufficient force to hold the printer in place until the release is activated.