Replication and Tribological Engineering of Physical Surfaces Using Two-Photon Lithography

Student: Shelby Maddox

Degree: Ph.D., May 2021

Major Professor: Dr. Min Zou

Research Area(s):

Conventional Materials & Processes

Nanoscience & Engineering

Background

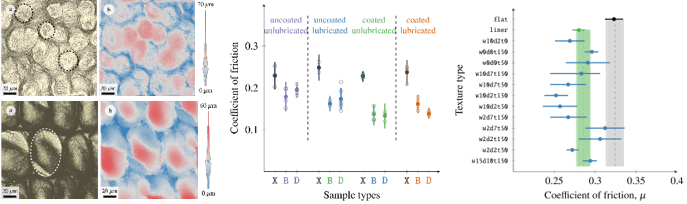

- Replication techniques are difficult to apply to many biosurfaces, and large amounts of data are difficult to process for fabrication.

- Nearly 10% of all automotive energy waste comes from the interface between the piston compression ring and the cylinder liner.

- There is a need to reduce this friction using surface texturing

Innovation

- A digitization and tiling process is applied to scanned height data to reduce processing need and expand replication capability.

- Hierarchical textures can be combined with biomimetic designs.

- Inspiration from nature can be used to improve friction.

.Approach

Learning from nature

- What biostructures do natural surfaces use to reduce friction?

- The designs are created with 3D modeling software. Two photon lithography to create physical structures

- Printing process allows quick turnaround of testing and development cycle.

- Truly 3D surfaces can be created not just extruded shapes. Digitization and replication by tiling

- Digitization of surfaces allows non contact replication of topographies.

- Other fields using tiling processes to generate large outputs from small inputs.

Key Results

- Results show significant friction reduction due to special combination of surface features, published in Journal of Tribology.

- Paper published in Journal of Manufacturing Processes on surface replication of biological surfaces, and in Biointerphases on friction reduction from those surface topographies.

Potential Applications

- Quick testing cycle of parameter-modified surfaces before robust, complex fabrication.

- Reduction of friction in lubricated interfaces.

Future/Ongoing Work

- Many bioinspired designs can be studied nondestructively.

- Impact of textures in industrial materials