Reduced Graphene Oxide-Nanosheet/Polybenzimidazole Composite Membranes for High Temperature Proton Exchange Membrane Fuel Cell Applications

Student: Thomas McKean III

Degree: M.S., August 2020

Major Professor: Dr. Ryan Tian

Research Area(s):

Nanoscience & Engineering

Conventional Materials & Processes

Background/Relevance

-

Increasing the operating temperature of proton exchange membrane fuel cells (PEMFC) will increase efficiency and enable the development of less expensive materials

-

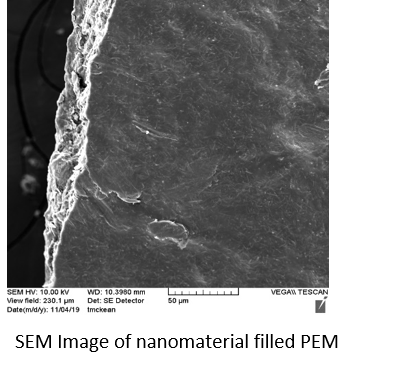

Nanomaterial filler in the PEM introduces additional proton conductivity and reduces degradation caused by the phosphoric acid (PA) proton transport medium, increasing the durability and performance of the PEMFC

Innovation

- Boosted proton conductivity of reduced graphene oxide(RGO)-based composite nanomaterial offers superior acid resistance, proton conduction, and mechanical reinforcement

Approach

- Hydrothermally synthesize proton conductive RGO nanomaterial composite, including additional functionalization for increased proton conductivity and nano-blending

- Drop cast PBI PEMs containing a range of concentrations of nanomaterial filler and observe their PA uptake

- Characterize the mechanical properties and proton conductivities of PEM’s over a range of nanomaterial content, PA content and temperatures

- Create membrane electrode assembly (MEA) using new PEM’s to test PEMFC performance.

Key Results

- RGO composite and subsequent protonation to introduce proton conductivity successfully performed

- Strong nano-blending between PBI and RGO composite confirmed

- New PEMs with different filler concentrations formed, further optimization ongoing

Conclusions

-

A proton-rich RGO composite nanomaterial with great PEM filler potential can be hydrothermally synthesized at a low cost

-

The nano-blending between PBI and RGO can be optimized to effectively mass produce advanced PEMs

Future Work

-

Synthesize composite nanomaterial using functionalized RGO

-

Investigate the filler’s ability to increase the mechanical properties of the membrane and decrease acid leeching

-

Quantify the proton conductivity and test MEA performance at different temperatures and PA loadings

-

Assess the potential to form RGO composites with advanced proton conducting materials